Unleashing Performance and Reliability with the Best Custom Camshafts Manufacturers in the Industry

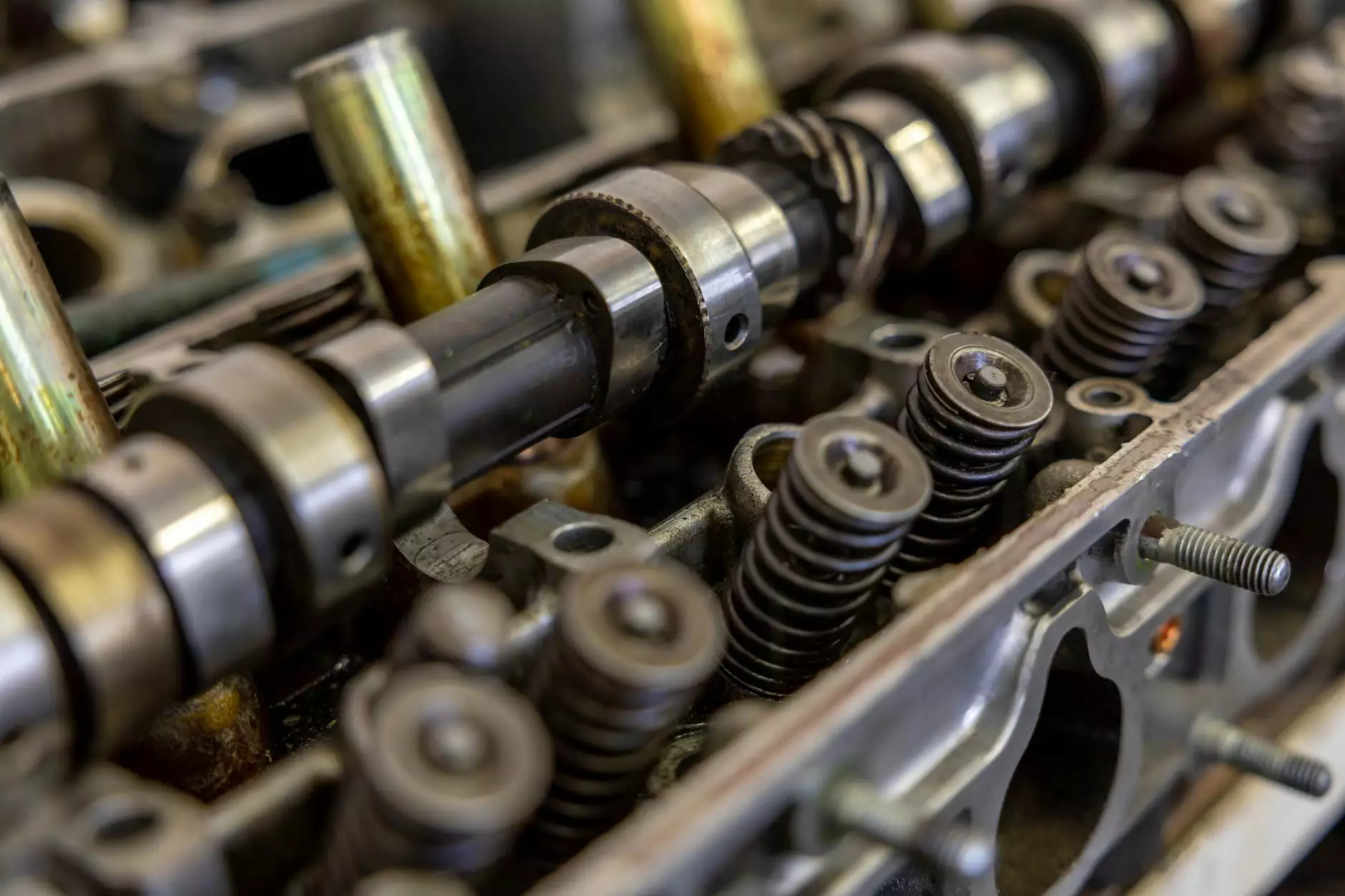

In the highly competitive realm of diesel engine parts and automotive manufacturing, custom camshafts manufacturers play a pivotal role in enhancing engine performance, fuel efficiency, and durability. As a cornerstone component in internal combustion engines, camshafts are responsible for controlling valve timing, opening and closing the engine's valves with precise synchronization. The demand for high-quality, customized camshafts has surged as automotive enthusiasts, commercial fleet operators, and engine builders seek tailored solutions that meet specific power, efficiency, and longevity requirements.

Why Choosing the Right Custom Camshafts Manufacturers Matters for Your Diesel Engine

The quality and design of your custom camshafts directly impact engine performance, emissions, and lifespan. Unlike mass-produced components, custom camshafts are engineered to match unique engine configurations, driving conditions, and performance goals. Partnering with reliable custom camshafts manufacturers ensures that your components are crafted with precision, using advanced materials and manufacturing processes that deliver optimal results.

Key Benefits of Working with Top Custom Camshafts Manufacturers

- Enhanced Performance: Custom profiles maximize airflow, improve torque, and boost horsepower.

- Improved Fuel Efficiency: Precise valve timing reduces fuel consumption and emissions.

- Durability and Longevity: High-quality materials and manufacturing methods ensure long service life.

- Engine Compatibility: Tailored solutions fit specific engine models for seamless integration.

- Innovation and Customization: Collaboration with manufacturers to develop unique camshaft profiles for specialized applications.

How to Identify Leading Custom Camshafts Manufacturers

Selecting a credible custom camshafts manufacturer involves evaluating several critical factors:

- Experience and Expertise: Manufacturers with decades of experience bring deeper insights and refined manufacturing techniques.

- Customized Design Capabilities: Ability to develop bespoke camshaft profiles tailored to your specific engine and performance goals.

- Material Quality: Use of premium, heat-resistant, and wear-proof materials such as hardened steel, billet, or exotic alloys.

- Manufacturing Precision: Advanced CNC machining, grinding, and testing processes ensure tight tolerances and high-quality finishes.

- Certifications and Compliance: ISO, TS16949, or other relevant certifications affirm adherence to international quality standards.

- Comprehensive Support: Technical consultation, testing, and after-sales support to optimize engine assembly and performance.

Innovative Manufacturing Technologies in Custom Camshaft Production

The latest technological advances have revolutionized the manufacturing of custom camshafts. Cutting-edge CNC machining centers enable precise shaping of complex profiles, while surface treatment techniques like nitriding and shot peening enhance wear resistance. Additionally, computer-aided design (CAD) and finite element analysis (FEA) tools allow manufacturers to simulate performance and stress points before production, optimizing durability and efficiency. These innovations empower custom camshafts manufacturers to deliver components that excel in demanding conditions, whether for commercial trucks, heavy machinery, or high-performance engines.

Material Selection: The Backbone of Quality Custom Camshafts

The selection of materials is fundamental to producing custom camshafts that withstand extreme operating environments. High-quality steel alloys, such as 8620, 4140, or billet steels, are preferred for their strength and machining properties. Heat treatment processes like induction hardening increase surface hardness, protecting against wear and fatigue. For high-performance applications, some manufacturers incorporate exotic materials like titanium or composites to further improve strength-to-weight ratios and corrosion resistance. Choosing the right materials ensures that your custom camshafts not only meet but exceed industry expectations.

Types of Custom Camshafts and Their Applications

Custom camshafts are designed to serve diverse engine demands. Understanding the different types helps in selecting the most suitable for your needs:

- Standard Custom Camshafts: Designed to match OEM specifications with minor modifications for enhanced performance or efficiency.

- Performance Camshafts: Engineered to maximize horsepower and torque, suitable for racing, high-performance vehicles, and custom builds.

- Eco-Friendly Camshafts: Focused on reducing emissions and improving fuel economy, complying with environmental regulations.

- Heavy-Duty Camshafts: Built for industrial engines and heavy machinery requiring robust, wear-resistant components.

Integration of Custom Camshafts into Diesel Engines for Optimal Results

Integrating custom camshafts into diesel engines can significantly elevate engine performance when paired with other high-quality diesel engine parts and accessories. Proper matching of camshaft profiles with fuel injectors, turbochargers, and exhaust systems ensures balanced airflow and combustion efficiency. Custom camshaft profiles allow for fine-tuning valve timing to suit specific applications, whether for increased power, better emissions control, or fuel economy.

The Role of Spare Parts Suppliers in Building Reliable Diesel Engines

The spare parts suppliers integrated with Client-Diesel.com offer an extensive range of premium diesel engine components, from pistons and injectors to turbochargers and valves. Working with reputable suppliers ensures that every engine part, including custom camshafts, meets stringent quality standards for durability and performance. These components are essential for maintaining engine reliability, reducing downtime, and achieving peak efficiency in various operational environments.

Choosing the Right Partner: Why Client-Diesel.com Is Your Ideal Custom Camshafts Manufacturers & Diesel Parts Supplier

At Client-Diesel.com, we pride ourselves on being a leading custom camshafts manufacturers and trusted spare parts supplier in the diesel engine industry. Our commitment to innovation, quality, and customer satisfaction has positioned us at the forefront of the market. Our manufacturing processes employ the latest technology, ensuring precision and durability in every product we deliver.

Our team of experienced engineers collaborates closely with clients to develop bespoke camshaft profiles tailored to their specific requirements. We source only premium materials and utilize rigorous testing protocols to guarantee performance and longevity. Whether you operate a fleet of commercial trucks, industrial machinery, or high-performance racing engines, our custom solutions are crafted to elevate your engine's capabilities.

Conclusion: Elevate Your Engine Performance with the Best Custom Camshafts Manufacturers

Achieving exceptional engine performance and reliability starts with partnering with the right custom camshafts manufacturers. Their expertise, innovative manufacturing capabilities, and commitment to quality directly influence your engine's efficiency, durability, and power output. When combined with high-quality diesel engine parts and a dependable spare parts supplier like Client-Diesel.com, you set the foundation for a robust, high-performing engine system designed to excel under demanding conditions.

Invest in custom camshaft solutions today to unlock your engine’s full potential—experience the difference that precision engineering and expert craftsmanship can make in your automotive or industrial operations.